About our Consultancy Services

Our team of technical experts provides comprehensive support for both Greenfield and Brownfield projects. Whether you’re building a brand new facility (Greenfield) or optimizing an existing one (Brownfield), we have the knowledge and experience to guide you through every stage. We understand the unique challenges faced by steel plants and various industries.

Our team can help you identify

areas for improvement and implement strategies to:

- Increase operational efficiency

- Achieve business excellence

- Partner with us to unlock the full potential of your steel plant or industrial facility.

Steel Plants Consultancy

Balaji Prime Steels offers comprehensive consultancy services for steel plant projects, covering all stages of the project lifecycle. Our expertise includes:

- Project Planning & Feasibility Studies: We assist in developing detailed project plans, conducting feasibility studies, and assessing the viability of new steel plants or expansions.

- Technological Selection: We help you choose the most appropriate and efficient technologies for your steel plant, considering factors such as raw material availability, production capacity, and cost-effectiveness.

- Engineering & Design: Our team can provide support in engineering and design aspects of the steel plant, ensuring optimal layout and efficient operations.

- Equipment Selection & Procurement: We can assist in selecting and procuring the necessary equipment for your steel plant, leveraging our network of trusted suppliers.

- Construction Management: We offer construction management services to ensure your steel plant is built on time and within budget.

- Rolling Mills: TMT Bar mill , wire rod mills,Hot strip mill, cold rolling mills,Hollow sections /pipe mills ,plate mill,steckel mill,Galvanizing line ,color coating line and GP/GC Service centre.

- Rail mill: Green field project,operations manufacturing , quality assurance ,Govt. approvals etc. For short rails -13 , 18 , 26 meters. Long rails – 121 , 260 meters Head Hedened rails for high speed trains ( 320 KMS/HR)- Project and operations etc. UIC60 E1, IRS 52, Etc, & ALL NATIONAL AND INTRNATIONAL STANDARADS.

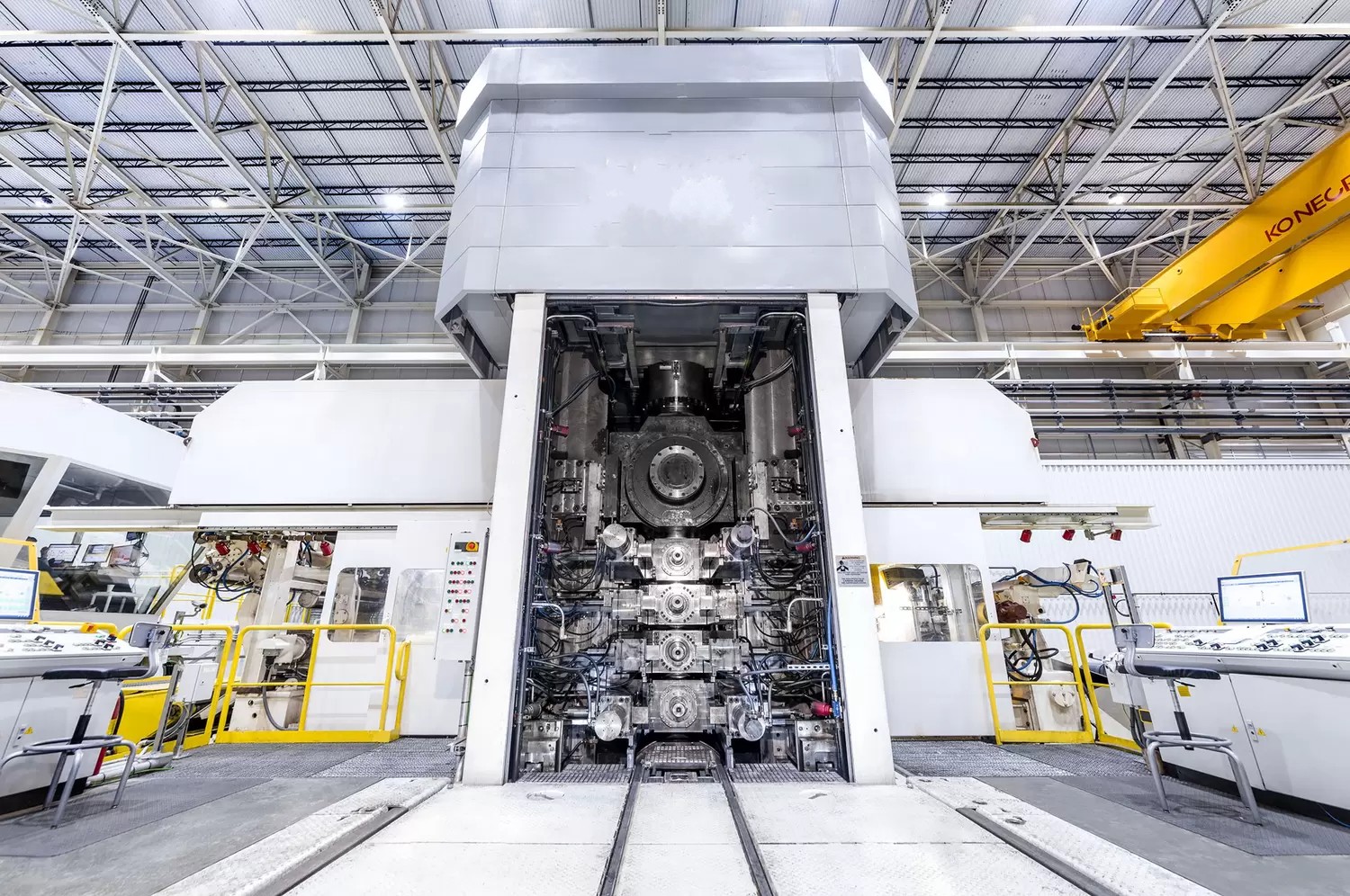

Rolling Mills Consultancy

Balaji Prime Steels offers specialized consultancy services for rolling mill projects, covering a range of mill types:

- TMT Bar Mill: Expertise in design, installation, and operation of TMT (Thermo-Mechanically Treated) bar mills, optimizing production of high-strength reinforcement bars.

- Wire Rod Mill: Consultancy for wire rod mills, focusing on efficient production of wire rod for various applications.

- Section/Structural Mill: Support for section and structural mills, specializing in the production of beams, columns, channels, angles, and other structural shapes.

- Wire Drawing Line: Guidance on setting up and managing wire drawing lines for producing various sizes and types of wire.

Galvanizing Lines Consultancy

Balaji Prime Steels offers expert consultancy services for galvanizing line projects, assisting you in establishing and optimizing efficient and high-quality galvanizing operations. Our services cover:

- Project Planning & Feasibility Studies: We help you develop detailed project plans, assess the feasibility of setting up a galvanizing line, and determine the optimal capacity and configuration.

- Technology Selection & Equipment Procurement: We guide you in selecting the most suitable galvanizing technology and equipment based on your specific needs and budget, leveraging our extensive network of suppliers.

- Engineering & Design: Our team provides support in the engineering and design aspects of the galvanizing line, ensuring efficient layout, material flow, and process optimization.

- Installation & Commissioning: We can oversee the installation and commissioning of the galvanizing line, ensuring smooth startup and efficient operation.

- Process Optimization & Efficiency Improvement: We help you optimize the galvanizing process to achieve high-quality coatings, minimize costs, and maximize productivity.

- Quality Control & Testing: We assist in establishing robust quality control procedures and testing protocols to ensure consistent coating quality and adherence to industry standards.

Cold Rolling Mill Consultancy

Balaji Prime Steels offers specialized consultancy services for cold rolling mill projects. Our expertise covers:

- Project Planning & Feasibility Studies: We assist in developing detailed project plans, conducting feasibility studies, and assessing the viability of new cold rolling mills or expansions.

- Technological Selection: We help you choose the most appropriate and efficient cold rolling technologies for your specific needs, considering factors such as desired product range, production capacity, and cost-effectiveness.

- Engineering & Design: Our team can provide support in engineering and design aspects of the cold rolling mill, ensuring optimal layout and efficient operations.

- Equipment Selection & Procurement: We can assist in selecting and procuring the necessary equipment for your cold rolling mill, leveraging our network of trusted suppliers.

- Operations Management: We can provide guidance and support in managing the day-to-day operations of your cold rolling mill, optimizing production and efficiency.

- Quality Control & Assurance: We help implement robust quality control and assurance systems to ensure the highest standards of product quality for your cold rolled steel products.

Hot Strip Mill Consultancy

Balaji Prime Steels offers specialized consultancy services for Hot Strip Mill projects. Our expertise covers the entire spectrum of Hot Strip Mill operations, from project planning and implementation to optimization and modernization. We assist with:

- Project Planning & Feasibility Studies: Detailed planning and feasibility studies to assess the viability and scope of your Hot Strip Mill project.

- Technological Selection: Guidance in selecting the most appropriate and efficient hot rolling technology for your specific needs, considering factors like production capacity, product mix, and budget.

- Engineering & Design: Support in the engineering and design of the Hot Strip Mill, ensuring optimal layout, efficient material flow, and safe operations.

- Equipment Selection & Procurement: Assistance in selecting and procuring the necessary equipment, leveraging our network of trusted suppliers and ensuring cost-effectiveness.

- Commissioning & Start-up: Expert support during the commissioning and start-up phases of your Hot Strip Mill, ensuring smooth and efficient operations from day one.

- Operations Management & Optimization: Ongoing support in managing and optimizing the operations of your Hot Strip Mill, maximizing productivity, minimizing downtime, and improving product quality.

- Modernization & Upgrades: Consultancy services for modernizing existing Hot Strip Mills, enhancing their performance, and extending their lifespan.

HR Plate/Steckel Mill Consultancy

Balaji Prime Steels offers specialized consultancy services for Hot Rolled (HR) Plate and Steckel Mill projects. Our expertise covers the entire project lifecycle, from initial planning and feasibility studies to commissioning and ongoing operational support. We provide guidance on:

- Project Planning & Feasibility: Assessing the viability of HR plate/Steckel mill projects, including market analysis, capacity planning, and financial modeling.

- Technology Selection: Helping you choose the most suitable technology for your specific needs, considering factors like product range, production volume, and cost-effectiveness.

- Engineering & Design: Providing support in the engineering and design aspects of the mill, ensuring optimal layout, equipment selection, and efficient operations.

- Equipment Procurement & Commissioning: Assisting in the selection and procurement of equipment, as well as overseeing the commissioning process to ensure smooth start-up.

- Operations Management & Optimization: Offering guidance and support in managing and optimizing the operations of your HR plate/Steckel mill, maximizing efficiency and productivity.

- Quality Control & Assurance: Helping implement robust quality control systems to ensure the production of high-quality HR plates and Steckel mill products.

Rail Mill Consultancy

Balaji Prime Steels offers comprehensive consultancy services for rail mill projects, covering all aspects from project inception to ongoing operations. Our expertise includes:

- Project Planning & Execution: We assist in developing and executing rail mill projects, ensuring efficient planning and timely completion.

- Technological Selection: We help you choose the most suitable and advanced technologies for your rail mill, considering factors such as desired rail types, production capacity, and cost-effectiveness.

- Operations Management: Our team can provide guidance and support in managing the day-to-day operations of your rail mill, optimizing production processes and maximizing efficiency.

- Quality Control: We help implement rigorous quality control systems to ensure the production of high-quality rails that meet or exceed industry standards.

- Technical Approvals: We facilitate obtaining necessary technical approvals from relevant approving agencies for both low-speed UIC-60 rails and high-speed HH rails (including rails for bullet trains), ensuring compliance and market access.

Hollow section Mill

Balaji Prime Steels offers specialized expertise and consultancy services for hollow section mills, focusing on the production of square and rectangular hollow sections. Our services cover:

- Project Planning & Feasibility Studies: We assist in developing detailed project plans and conducting thorough feasibility studies for establishing or expanding hollow section mills.

- Technological Selection: We guide you in selecting the most suitable and advanced technologies for producing high-quality square and rectangular hollow sections, considering factors like production capacity, material specifications, and cost-effectiveness.

- Engineering & Design: Our team can provide support in the engineering and design aspects of the mill, ensuring optimal layout, efficient material flow, and smooth operations.

- Equipment Selection & Procurement: We leverage our industry connections to help you select and procure the necessary equipment for the hollow section mill, ensuring quality and competitive pricing.

- Operations Management: We offer guidance and support in managing the day-to-day operations of your hollow section mill, optimizing production processes, and ensuring consistent quality.

- Quality Control & Assurance: We help implement robust quality control systems to ensure the square and rectangular hollow sections meet the required industry standards and customer specifications.